SPR Slurry Pump Wear Parts

SPR Slurry Pump Casing

Rubber Slurry Pump Body (Casing) interchangeable with Warman SPR series Rubber Vertical Slurry Pumps

We offer a variety of rubber casing, so that customers can apply in a variety of complex environments.

RUBBER MATERIALS TYPE AND DATA DESCRIPTIONS

| Code | Material name | Type | Description |

| YR26 | Anti-thermalBreakdown Rubber | Natural Rubber | YR26 is a black, soft natural rubber. It has superior erosion resistance to all other materials in fine particle slurry applications. The antioxidants and anti-degradants used in RU26 have been optimized to improve storage life and reduce degradation during use. The high erosion resistance of RU26 is provided by the combination of its high resilience, high tensile strength and low Shore hardness. |

| YR33 | Natural Rubber(Soft) | Natural Rubber | YR33 is a premium grade black natural rubber of low hardness and is used for cyclone and pump liners and impellers where its superior physical properties give increased cut resistance to hard, sharp slurries. |

| YR55 | Anti-thermalNatural Rubber | Natural Rubber | YR55 is a black, Anti-corrosive natural rubber. It has superior erosion resistance to all other materials in fine particle slurry applications. |

| YS01 | EPDM Rubber | Synthetic Elastomer | |

| YS12 | Nitrile Rubber | Synthetic Elastomer | Elastomer YS12 is a synthetic rubber which is generally used in applications involving fats, oils and waxes. S12 has moderate erosion resistance. |

| YS31 | ChlorosulfonatedPolyethylene (Hypalon) | Synthetic Elastomer | YS31 is an oxidation and heat resistant elastomer. It has a good balance of chemical resistance to both acids and hydrocarbons. |

| YS42 | Polychloroprene (Neoprene) | Synthetic Elastomer | Polychloroprene (Neoprene) is a high strength synthetic elastomer with dynamic properties only slightly inferior to natural rubber. It is less effected by temperature than natural rubber, and has excellent weathering and ozone resistance. It also exhibits excellent oil resistance. |

The rugged SP/SPR Heavy Duty Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel

and almost every other tank, pit or hole in the ground slurry handling situation.

The SP/SPR design with either hard metal (SP) or elastomer covered (SPR) components makes it ideal for:

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

• Heavy duties demanding cantilever shafts

*SPR RUBBER LINED VERTICAL SLURRY PUMPS CASING DATA

| Model | Casing code | Rubber material | Product Weight (KG) |

| 40PV-SPR | SPR4092 | R26, R55, R33, S01, S10, S12, S31, S42 | 11.2 |

| 65QV-SPR | SPR 65092 | R26, R55, R33, S01, S10, S12, S31, S42 | 36.2 |

| 100RV-SPR | SPR10092 | R26, R55, R33, S01, S10, S12, S31, S42 | 64.6 |

| 150SV-SPR | SPR15092 | R26, R55, R33, S01, S10, S12, S31, S42 | 120 |

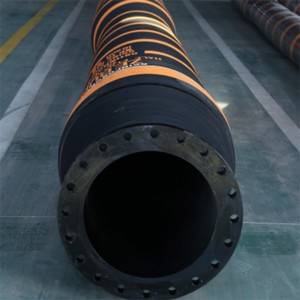

SPR Slurry Pump Column

*We offer columns of various sizes to ensure that you can use them at any underground depth

*Unique adhesive rubber process to meet all kinds of acid-base media

*High quality flange, standard screw hole, more convenient and fast installation

SPR VERTICAL SLURRY PUMP STRUCTURE CHART

*SPR SLURRY PUMPS COLUMN DATA

| Model | Back Liner code | Rubber material | Length (MM) |

| 40PV-SPR | PVR4102* | R26, R55, R33, S01, S10, S12, S31, S42 | 600.900.1200.1500.1800 |

| 65QV-SPR | QVR65102* | R26, R55, R33, S01, S10, S12, S31, S42 | 600.900.1200.1500.1800 |

| 100RV-SPR | RVR10102* | R26, R55, R33, S01, S10, S12, S31, S42 | 600.900.1200.1500.1800 |

| 150SV-SPR | SPR15102* | R26, R55, R33, S01, S10, S12, S31, S42 | 600.900.1200.1500.1800 |

SPR Slurry Pump Open Impeller

-The impeller has large and open passages and can transfer the slurry effectively, providing good dynamic and static balance to achieve little vibration and low noise in operation.

-The open type impeller exhibits higher efficiencies and is less prone to wear in the front liner region.

-Higher productivity, increased profitability and ease maintenance

-Double suction impellers create low axial bearing loads, increasing bearing life

*SPR RUBBER LINED VERTICAL SLURRY PUMPS IMPELLER DATA

| Model | Impeller code | Rubber material | Product Weight (KG) |

| 40PV-SPR | SPR4206 | R26, R55, R33, S01, S10, S12, S31, S42 | 1.4 |

| 65QV-SPR | SPR65206A | R26, R55, R33, S01, S10, S12, S31, S42 | 6.2 |

| 100RV-SPR | SPR10206A | R26, R55, R33, S01, S10, S12, S31, S42 | 13.4 |

| 150SV-SPR | SPR15206A | R26, R55, R33, S01, S10, S12, S31, S42 | 29 |

SPR Slurry Pump Discharge Pipe

*We offer discharge pipe of various sizes to ensure that you can use them at any underground depth

*High quality flange, standard screw hole, more convenient and fast installation

*Unique adhesive rubber process to meet all kinds of acid-base media

Type SP\SP(R) pumps are vertical, centrifugal slurry pumps which are submerged in sump to work. They are designed for delivering abrasive, large particle and high-density slurries. These pumps do not need any shaft seal and sealing water. They can also be operated normally for insufficient suction duties.

All parts of type SP(R) pump immersed in liquid are lined with rubber. They are suited to transport the slurry which contains non-edge and abrasive particle.

Wet parts of type SP pumps are made of abrasion-resistant metal.

*SPR SLURRY PUMPS DISCHARGE PIPE DATA

| Model | Back Liner code | Rubber material | Length (MM) |

| 40PV-SPR | PVR4154* | R26, R55, R33, S01, S10, S12, S31, S42 | 600, 900, 1200, 1500, 1800 |

| 65QV-SPR | QVR65154* | R26, R55, R33, S01, S10, S12, S31, S42 | 600, 900, 1200, 1500, 1800 |

| 100RV-SPR | RVR10154* | R26, R55, R33, S01, S10, S12, S31, S42 | 600, 900, 1200, 1500, 1800 |

| 150SV-SPR | SPR15154* | R26, R55, R33, S01, S10, S12, S31, S42 | 600, 900, 1200, 1500 |

SPR Slurry Pump Rubber Back Liner

Features of SPR vertical slurry pump:

1) High Efficiency Non-block up

The uniquely designed single, double-gate impeller, opening model, double leaf model impeller is high effective without block-up, the pump casing etc. flow- through parts designed for completing with the impeller can be selected with their materials and models upon the transported media and can be made sure of the excellent hydraulic performance and working life in the transportation of the media containing suspended grains and long fibers, corrosive and abrasive.

2) Stable; Durable without vibration

Vertical slurry pump is vertically structured, the drive unit (motor stand, clutch, drive shaft, connecting stand, bearing) is modular designed and can be superposed at will along with the variation of the under-water depth. Both pump casing and impeller can be placed under liquid by 0.5-10m and the motor above the liquid surface, then, via connection with the drive unit, directly drives the non-block impeller to stably run without vibration.

3) Easy use; Long durability

The impeller is submerged in water and easy to start. An automatic liquid-level control cabinet can be fitted with required by users so as to get the liquid-level to control the pumps starting and stopping, without need of a special person to look after.

Solid maintenance-free design, good rigidity of the pump shaft and fully-closed roller bearing of a famous brand. The pre-injected high-temperature withstanding lubricating grease

*SPR Rubber Lined Vertical Slurry Pumps Back Liner data:

| Model | Back Liner code | Rubber material | Product weight (KG) |

| 40PV-SPR | SPR4041 | R26, R55, R33, S01, S10, S12, S31, S42 | 5.6 |

| 65QV-SPR | SPR65041 | R26, R55, R33, S01, S10, S12, S31, S42 | 25 |

| 100RV-SPR | SPR10041 | R26, R55, R33, S01, S10, S12, S31, S42 | 31 |

| 150SV-SPR | SPR15041 | R26, R55, R33, S01, S10, S12, S31, S42 | 65 |

FEATURES

Setting depths from 0.9m to 2.4m

Concentric casing minimizes shaft load over wide operating ranges and reduces wear

Simple installation

Cantilever design so there are no submerged bearings or shaft seals

Cast bearing housings result in increased critical speeds and lower vibration levels than legacy equipment

Can run dry (snore) continuously

Large impeller passages means a reduced risk of blockage

Top and bottom inlets are suitable for snore conditions, with no need for priming and self-venting

Available in a pre-fabricated conical sump with quick clean facilities

Replaceable strainers allows for easy maintenance

Ease of maintenance