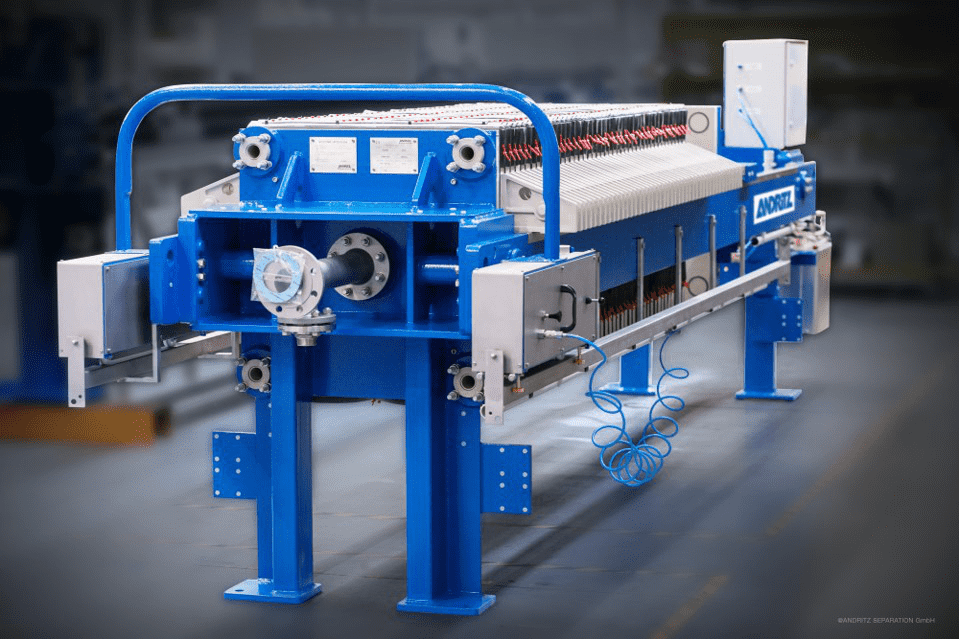

In the field of mechanical manufacturing, Arex’s rubber and plastic products almost covered a variety of equipment, it can be a very small accessories, it can also be a very large customized products, such as seals, hose, plastic joints and custom-made part of various kinds of rubber or plastic. As each customer’s needs are different, our design team and manufacturing team make every effort to take the customer’s economic interests into account, which bring the mold cost and product manufacturing costs to the maximum possible reduction, regular maintenance of mold equipment and timely communication with customers of raw material price fluctuations and other issues. In addition, the treatment of details is also an important link in the mechanical application of rubber and plastic products, many rubber and plastic products are often used in precision instruments or precision equipment, as important accessories or materials supplement, therefore, the precision of rubber and plastic products often determines the use of precision instruments and efficiency. For the customer groups within high requirements about rubber and plastic product quality and precision, Arex has a wealth of experience to do the corresponding service work and technical support. At the same time, Arex can also provide qualification data, quality testing, product testing and other factory business for some of customers of trading company. In the soon future, Arex will work continuously improve our service and product quality, improve operating costs, focus on product optimization and technology development, which will bring business support and development source power to more customers and enterprises.

Post time: Dec-02-2020