Manufacturing Companies for 8mm Rubber Hose - Rubber Lined Steel Pipes – Arex

Manufacturing Companies for 8mm Rubber Hose - Rubber Lined Steel Pipes – Arex Detail:

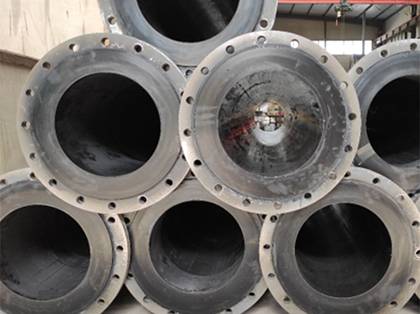

The rubber lined steel pipes are designed to be used in various abrasive pumping applications. Applications such as mill discharge, high pressure pumps, long tailings lines, demanding slurry pump applications and gravity pipes. Each end with vulcanized rubber seal fixed flange.

Wear-resistant and corrosion-resistant rubber lined steel pipe is made of common steel pipe as framework material and using with excellent properties of wear-resistant, corrosion-resistant and heat-resistant rubber as lining layer. It is compounded by special technology with high-performance adhesive. Mainly used in metallurgy, electric power, chemical industry, petroleum, coal, cement and other industries area. In the mining work, it is widely used in the mine tailings conveying system, coal mine backfilling and related pipe system fields. In particular, the pipeline is very suitable for conveying the temperature between -50°C to +150°C medium, which is easy to wear and corrosion. We can increase the wall thickness at the pipe corner according to the customer’s demand, thus extending the service life. Meanwhile, the service life of the rubber-lined steel pipe can reach 15-40 years in general. The pipe can be rotated nearly 90 degrees after 6-8 years of service. Each time of rotation can extend the serving life, Steel pipe can be repeatedly lined with rubber for three to four times, thus it reducing the use of costs in further.

Parts of specification for rubber-lined pipe

|

OD/mm |

Pipe wall thickness/mm |

Working pressure/MPa |

|

450 |

10~50 |

0~25.0 |

|

480 |

10~70 |

0~32.0 |

|

510 |

10~45 |

0~20.0 |

|

530 |

10~50 |

0~22.0 |

|

550 |

10~50 |

0~20.0 |

|

560 |

10~50 |

0~21.0 |

|

610 |

10~55 |

0~20.0 |

|

630 |

10~50 |

0~18.0 |

|

720 |

10~60 |

0~19.0 |

Physical Properties of rubber-lined pipe

| Item | Standard |

| Thickness of lining (MPa)≥ |

16.5 |

| The lining and the skeleton 180°peel strength (KN/m) ≥ |

8 |

| Elongation at the lining (%) ≥ |

550 |

| The lining of the lining is stretched (300%, MPa) ≥ |

4 |

| The lining layer atonal abrasion loss(cm³/1.61km) ≤ |

0.1 |

| Lining hardness (Sauer type A) |

60±5 |

| The rate of change of the intensity of the thermal ageing of the lining (70℃ x 72 h, %) ≤ |

10 |

Features

1. Excellent Construction

2. Good wear resistance and long service life

3. High strength and high impact resistance

4. Good corrosion resistance

5. Wide temperature range

6. Quick connection and easy installation

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for Manufacturing Companies for 8mm Rubber Hose - Rubber Lined Steel Pipes – Arex , The product will supply to all over the world, such as: New Orleans, Albania, Cambodia, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.