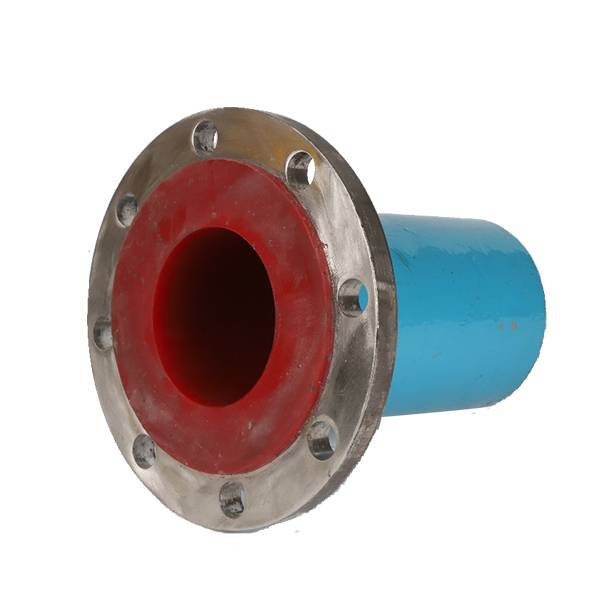

2020 High quality Rubber Stator And Rotor – Customized Plastic parts – Arex

2020 High quality Rubber Stator And Rotor – Customized Plastic parts – Arex Detail:

As one of the most competitive mold manufacturers and injection molding company in China. we serve a wide range of industry applications, including household application, auto, electronic, medical, agriculture, mining and etc.

Our services include:

- CAD design/mold flow analysis/DFM

- Custom injection mold, die-casting making

- Plastic injection molding

- Prototyping, small volume production

- Painting, skill printing, assembly

Introduction

Our injection molding shop equipped 12 sets of plastic injection molding machines, range from 40ton to 800 ton, we provide 24 hours a day, 7 days a week automatically production services. The plastic resin we selected covers a wide range, includes ABS, PC, PP, PA, PMMA, POM, PE etc.

We build the molds for plastic injection molding, at the beginning of the mold design, we take the injection molding into consideration, it allows us able to achieve the shortest molding cycle time, minimum maintenance cost, which would eventually benefit our customers. Low volume production orders are welcome as well, it always happened when customer feel the cost is unbearable especially the mold making cost. Our mold is able to provide a full range of solutions to lower down your budget for low volume project with good quality. Our experts work with you together to find the best solution for your companies.

We are experienced with various plastic injection molds for automotive, medication, lighting, sport equipment, home appliance, and agriculture. Currently we have 20 excellent engineers in our company, most of the them have good education in plastic injection molding industry, they take pride in their works, we are able to provide 20 sets of injection molds per month. To satisfy global companies’ highest requirements, we invest on the latest technology continuously and equipped the most advanced mold manufacturing facilities, we have full in-house plastic injection mold manufacturing, injection molding, painting, assembly capacity, our equipment includes but not limited to: 8 sets of CNC, precision 0.005mm; 14 sets of mirror EDM, 8 sets of slow wire cut, 12 sets injection molding machines range from 40 Ton to 800Ton, 1 set of 2d projection measurement, 1 set of CMM. We can build plastic mold and die-casting maximum 7.5 tons, molded plastic parts Maximum 1200g. We also use the advanced CAD/CAM/CAE system, we can work with data format in pdf, dwg, dxf, igs, stp etc.

Working Principle

The injection molding is a process to form the plastic resin into the desired shape. Injection molding machine press the melted plastic into the mold, and cool down by cooling system into solid designed shape, almost all thermoplastics using this method, comparing with other processing way, injection molding has advantage of accuracy, productivity, it has higher requirement for equipment and mold cost, so it is mainly for high-volume production of injection molded parts.

Injection molding machine commonly used plunger cylinder / screw cylinder. Injection molding process: feed the plastic raw material from the hopper into the barrel, the plunger starts to push, the plastic raw material is pushed into a heating zone and then through the bypass shuttle, the molten plastic through the nozzle into the mold cavity, then water or oil run through the designed cooling system to cool down the mold to get a plastic article. Injection molded parts from the mold cavity is typically required for proper treatment to remove the stress generated during molding process to have good dimensional stability and performance.

Six stages of plastic injection molding process

Plastic injection molding process begins with the gravity feeding of polyolefin pellets from a hopper into the injection unit of the molding machine. Heat and pressure are applied to the polyolefin resin, causing it to melt and flow. The melt is injected under high pressure into the mold. Pressure is maintained on the material in the cavity until it cools and solidifies. When the plastic part temperature lower than the material’s distortion temperature, the mold opens and the plastic part is ejected.

The complete injection process is called a molding cycle. The period between the start of the injection of the melt into the mold cavity and the opening of the mold is called the clamp close time. The total injection cycle time consists of the clamp close time plus the time required to open the mold, eject the plastic part, and close the mold again, the injection molding machine transfer the resin into molded parts through a melting down, injection, pack, and cool down cycle. A plastic injection molding machine includes the following major components as below.

Injection system: feed the raw materials into cylinder, heat up and melt it down, push the melted materials into the cavity through the spare.

Hydraulic system: to provide the force of injection.

Mold system: to load and assemble the mold.

Clamping system: to provide packing force.

Control system: to control action, cooling system.

Clamping force is commonly used to identify the capacity of the plastic injection molding machine, other parameters include shot volume, injection rate, injection pressure, screw, layout of inject bar, mold size, and the distance between tie bars. Plastic injection molding machines can be divided into several categories, besides general-purpose machines for normal plastic parts without high precision or unusual design, there are tight-tolerance machines especially for high precision parts, and high-speed machines for thin-wall parts.

A whole injection molding process includes following six steps

1) The mold closes and the screw begins moving forward for injection.

2) Filling, eject melted raw materials into the cavity.

3) Pack, the cavity is packed as the screw continuously moves forward.

4) Cooling, the cavity cools down as the gate freezes off and closed, the screw begins to retract to plasticize material for the next cycle.

5) Mold open and part ejection, the mold opens and parts are injected out by ejection system.

6) Close, the mold closes and the next cycle begins.

PO Procedure

From inquiry to PO closed, we have a standard procedure to follow, it helps both internal and customers always clear where we are. The transition of each step would be easier and smoother as well.

Order process of export injection plastic mold:

- Received 2D/3D part drawing from customer, project manager holds kick-out meeting to review data from customer with mold designers, mold makers, QA manager, PMC. Collect all the information have been discussed, send DFM report to customer for confirmation.

- DFM report contains all the necessary information before design and manufacture. Mold gating way, ejection way, layout of injection pins, layout of parts, mold parting line, cooling line. Special structure feature like sliders, angle lifters, finish of mold core and cavity, engraving etc.

- After all details have been discussed through, mold design start and 2d layout of mold design would be provided to customer within 1-3 days, mold design in 3D takes 3-7 days depends on the complexity of the mold.

- Send mold design to customer for approval, start to order mold steel, mold base, accessories after deposit. A process report would be submitted and show all the process planned. Weekly report would be follows as the mold manufacturing process move forwarder until it’s finished.

- The first time’s mold trial tells if all the mechanism of mold work properly, geometry of part is correct, we check mold cooling system, mold injection system, mold ejection system etc. after proper modification, T1 molded plastic samples would be submitted to customer together with dimension report, injection molding parameter. normally it’s 90% of perfection.

- Get comments for sample improvement, functionality, appearance, dimensionally after corrections, finish the texture/polishing, engraving, send the samples for final approval.

- Do a small automatically run and CPK report study to make sure tooling stability.

- Packing the mold with wooden box, if the mold shipped by sea, we pay specially attention to the vacuum packing to prevent from rusty. Packages include all 2d/3d mold design drawing, NC programming data, copper, spare parts, interchangeable inserts, etc.

- Follow up the work performance of the mold in customers’ plant and provide necessary services.

We can even fabricate large size plastic products as clients’ requirement, which is widely being used in mining, industrial, construction and so on. Please consult factory for special requirement.

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for 2020 High quality Rubber Stator And Rotor – Customized Plastic parts – Arex , The product will supply to all over the world, such as: Norwegian, Israel, Albania, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.